“In general, we tried all the consumer products. It works,” Saito told the visitors to his lab regarding the catalyst. Arifuzzaman told the crowd nylon was the most difficult plastic material to work with the catalyst, but the process just needs to be hotter for nylon to break down. “If it’s mixed, no problem,” Saito said regarding mixing different types of plastic. Currently, plastic recycling technology only works well with clean, single types of plastic products, he said.

He called inefficiency and inability to recycle mixed plastics a “bottleneck in plastics recycling.”

“Plastics have numerous benefits in our lives, but plastic waste management has become a global environmental crisis,” the lab stated in a promotional booklet. Only 9 percent of plastic waste, it stated, is recycled, most of which becomes lower value products.

“This process will not only reduce plastic waste entering landfills but will also add significant commercial value to current plastic wastes, opening a new paradigm of plastic recycling toward a net-zero carbon society,” according to ORNL communications.

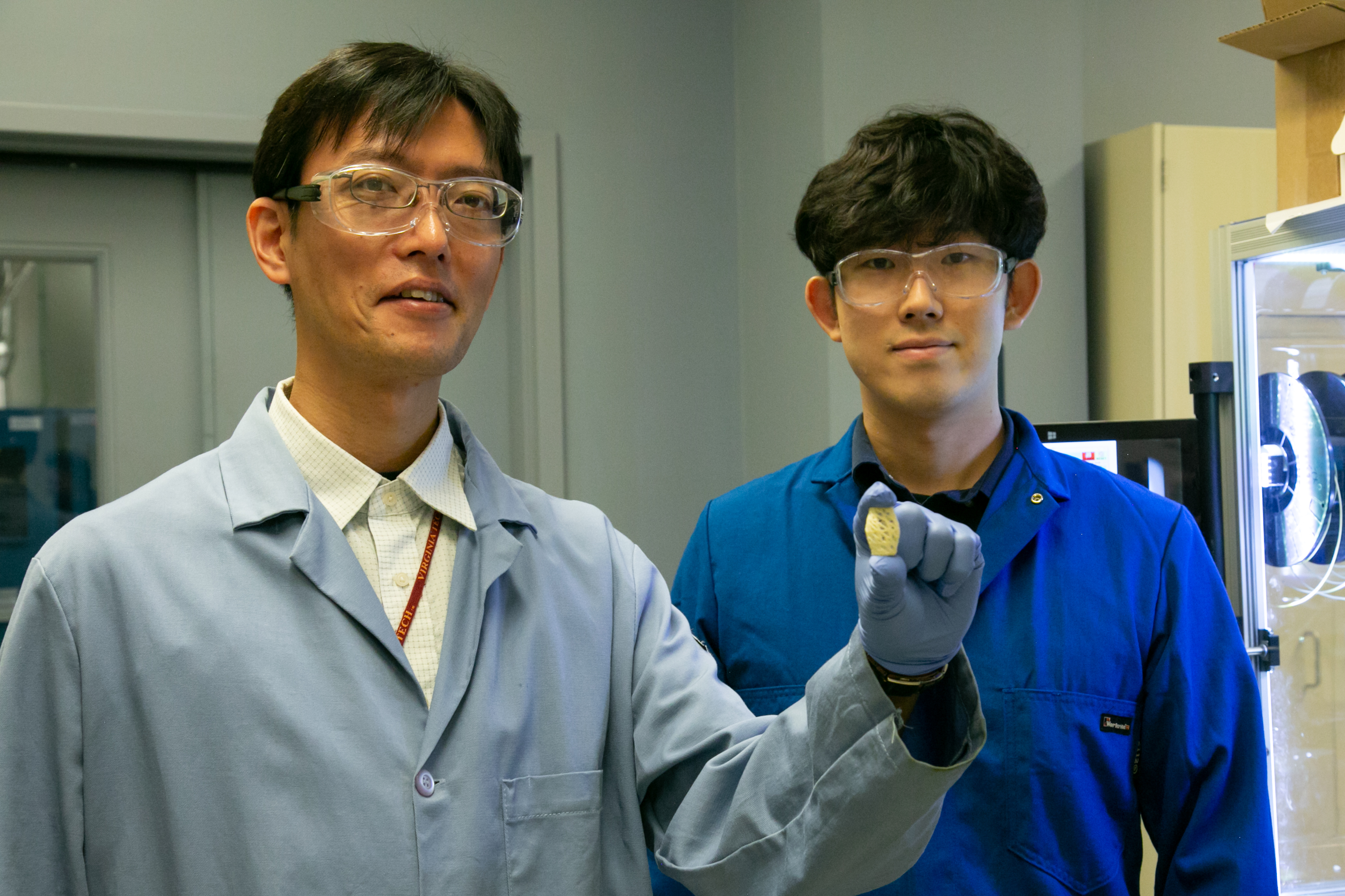

Earlier this year, Battelle, which runs ORNL for the Federal Department of Energy, named Saito the ORNL inventor of the year specifically for his “notable inventions in polymer upcycling.”

Saito develops the monomer via the process currently used for raw fossil fuels such as oil. These monomers can also be used for plastic resin and “plastic end-product production.” At present, Saito said, people tend to use petroleum-based monomers for producing these plastics rather than recycled ones.

Last the lab announced Saito’s team had developed a specific “upcycling approach” with one type of plastic. It allows for acrylonitrile butadiene styrene, used in auto parts, LEGO blocks and tennis balls, to be upcycled into an even more durable material.