Displaying items by tag: lithium battery recycling

ORNL chemists invent a more efficient way to extract lithium

Oak Ridge National Laboratory

Oak Ridge National Laboratory

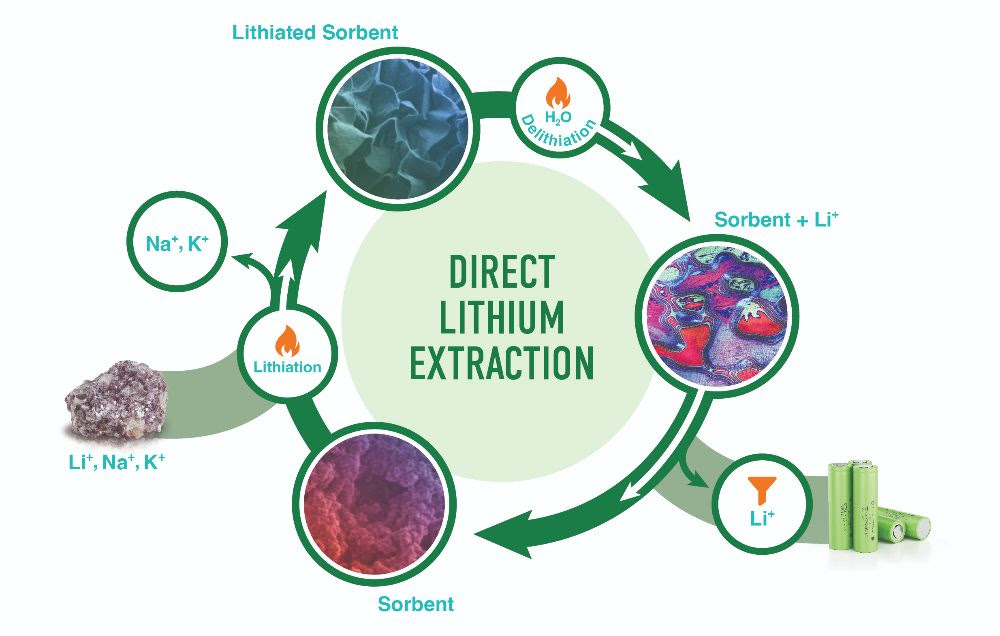

OAK RIDGE — Chemists at the Department of Energy’s Oak Ridge National Laboratory have invented a more efficient way to extract lithium from waste liquids leached from mining sites, oil fields and used batteries. They demonstrated that a common mineral can adsorb at least five times more lithium than can be collected using previously developed adsorbent materials.

“It’s a low-cost, high-lithium-uptake process,” said Parans Paranthaman, an ORNL Corporate Fellow and National Academy of Inventors Fellow with 58 issued patents. He led the proof-of-concept experiment with Jayanthi Kumar, an ORNL materials chemist with expertise in the design, synthesis and characterization of layered materials.

“The key advantage is that it works in a wider pH range of 5 to 11 compared to other direct lithium extraction methods,” Paranthaman said. The acid-free extraction process takes place at 140 degrees Celsius, compared to traditional methods that roast mined minerals at 250 degrees Celsius with acid or 800 to 1,000 degrees Celsius without acid.

Lithium is a lightweight metal commonly used in energy-dense and rechargeable batteries. Electric vehicles, which are needed to achieve net-zero emissions by 2050, rely on lithium-ion batteries. Industrially, lithium is extracted from brines, rocks and clays. The ORNL innovation may help meet rising demand for lithium by making domestic sources commercially viable.

Greener solution powers new method for lithium-ion battery recycling

ORNL researchers Lu Yu and Yaocai Bai examine vials that contain a chemical solution that causes the cobalt and lithium to separate from a spent battery, followed by a second stage when cobalt precipitates in the bottom. Carlos Jones/ORNL/DOE

ORNL researchers Lu Yu and Yaocai Bai examine vials that contain a chemical solution that causes the cobalt and lithium to separate from a spent battery, followed by a second stage when cobalt precipitates in the bottom. Carlos Jones/ORNL/DOE

OAK RIDGE — Used lithium-ion batteries from cell phones, laptops and a growing number of electric vehicles are piling up, but options for recycling them remain limited mostly to burning or chemically dissolving shredded batteries. The current state-of-the-art methods can pose environmental challenges and be difficult to make economical at the industrial scale.

The conventional process recovers few of the battery materials and relies on caustic, inorganic acids and hazardous chemicals that may introduce impurities. It also requires complicated separation and precipitation to recover the critical metals. However, recovering metals such as cobalt and lithium could reduce both pollution and reliance on foreign sources and choked supply chains.

This research is funded as a project of the Advanced Battery Recycling Consortium, or ReCell, a program of the Vehicle Technologies Office within DOE’s Office of Energy Efficiency and Renewable Energy. Lu Yu and Yaocai Bai and researchers Rachid Essehli and Anuj Bisht contributed to the study, which utilized the DOE’s Center for Nanophase Materials Science at ORNL.

— Oak Ridge National Laboratory